STORY

OUR THOUGHTS

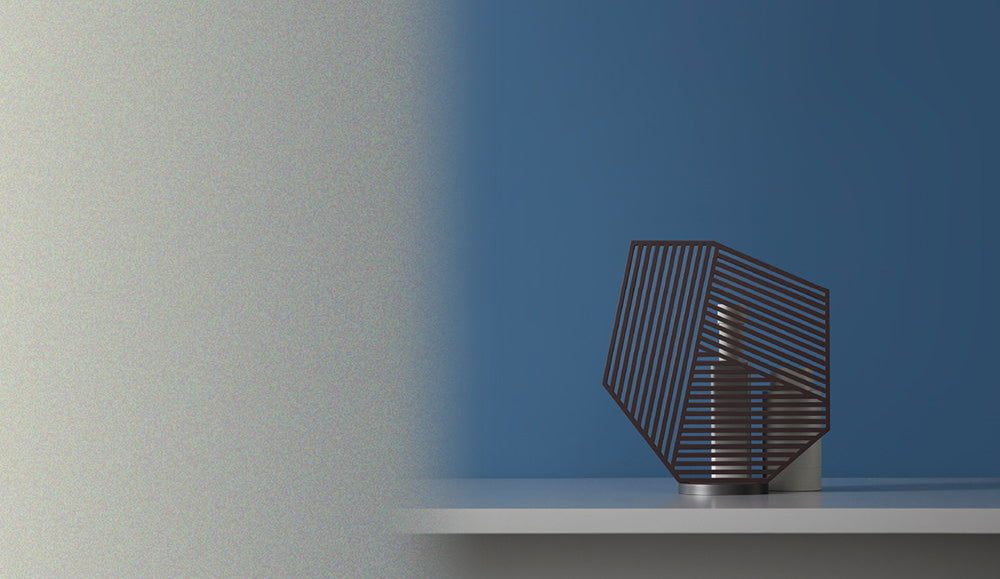

Breathing life into

the finest quality shoji scraps.

In manufacturing shoji screens, we carefully select the highest quality lumber and use the best lumber with controlled moisture content, but we also do not want to waste the best quality lumber, even if it is offcuts that are created in the manufacturing process.

OUR TEAM

OUR TEAM

PRODUCTION

製造

中井産業株式会社

https://www.nakaisangyo.co.jp

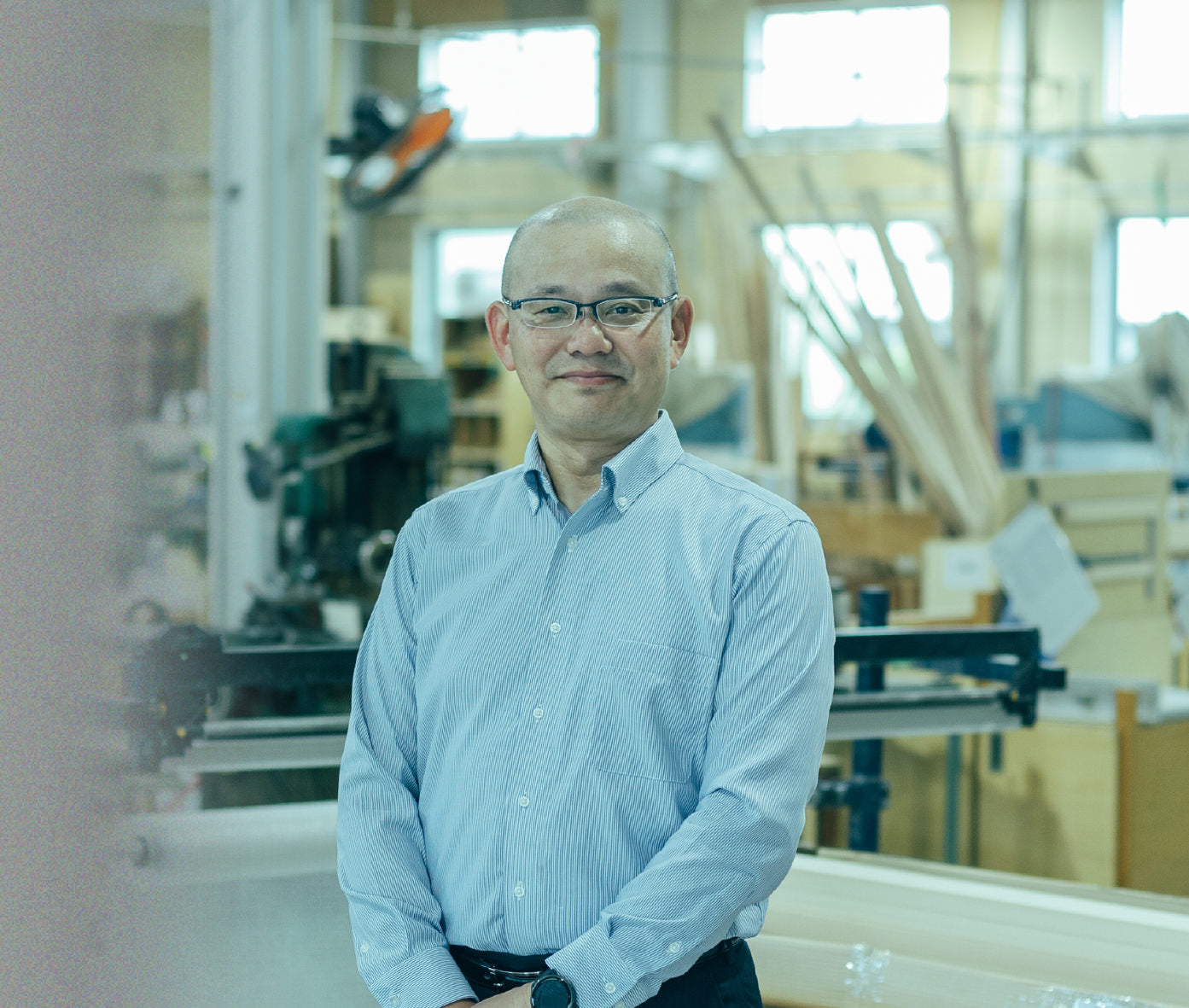

Nakai Sangyo Co., Ltd. began manufacturing wooden fittings in 1935 in Kishu, currently called Wakayama Prefecture. Wakayama has traditionally been a manufacturing base for fittings in the Western region of Japan, and we have made fittings ordered by other fitting makers in the same industry. By specializing in manufacturing, we have continuously improved our craftsmanship, trained young craftsmen, introduced the most advanced machinery, and launched our own brand, "KITOTE". Today, the company manufactures a full range of fixtures and custom woodwork products for homes, commercial stores, public facilities, kindergartens, nursing homes, shrines and temples, and more.

ARTISANT

Striving to create a wide-ranging opportunity for craftsmen

In an industry where the aging of craftsmen is a serious problem, we have craftsmen of all ages, from their 20s to their 70s. In the early 2000s, we predicted that a shortage of craftsmen would be inevitable in the future, and we sought to recruit and train young craftsmen.

In the beginning, the retention rate was low because we could not teach or support new employees after hiring, but once we incorporated a “brother system”, in which senior employees take new employees under their wings, the retention rate increased and technical improvement became faster. All of our craftsmen are working towards obtaining the Class-1 Joiner Technician Certificate, and three Class-1 technicians are teaching junior craftsmen.

In addition, since the days when shoji screens were mass-produced, women have been actively employed to work on NC machine tools. Today, a time when high-mix low-volume production is in demand, women are also expanding their work areas to become multi-skilled craftsmen, and female artisans are being born. Young aspiring craftsmen who join our company because they are attracted to our own brand of shoji screens, "KITOTE," are taught not by the old-fashioned "see and steal" method, but by explaining things clearly in words and showing numerical values as much as possible to deepen their understanding and increase their technical skills. Since we have many clients and receive custom-orders in a wide range of genres, there are few monotonous tasks, and we work in an environment where we are constantly learning.

ABOUT

CONTACT

For quotes, orders, questions about our products,

or any other inquiries, please feel free to contact us at the address below.

*Please make sure to write "About SHA/SHA" in the subject line.

or any other inquiries, please feel free to contact us at the address below.

*Please make sure to write "About SHA/SHA" in the subject line.